Our Plant

High Quality Production Cycle

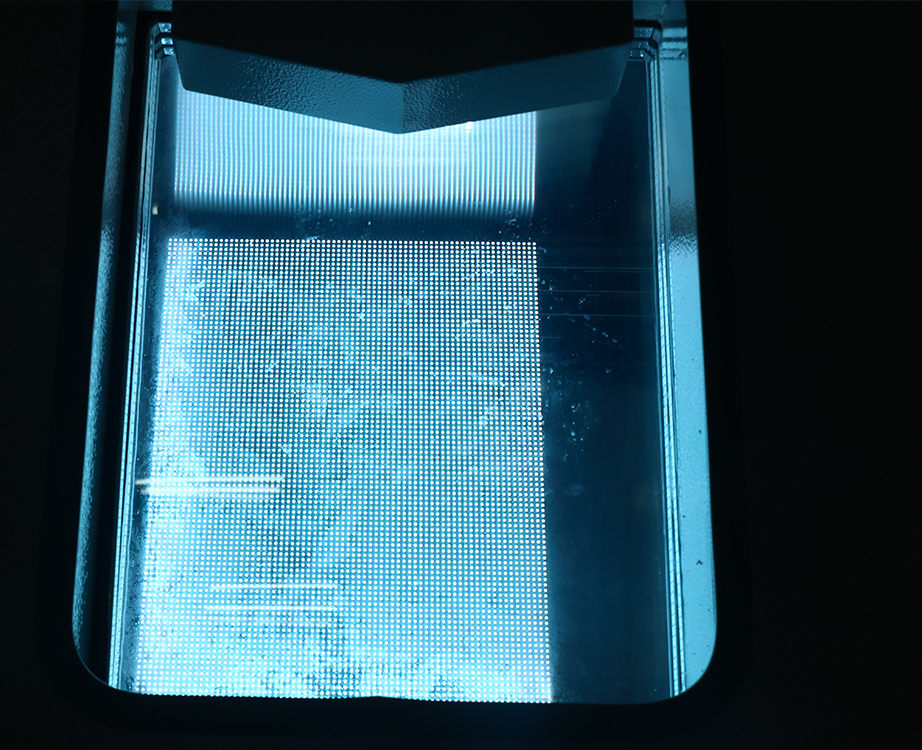

We have a dust-free manufacturing system that is strictly supervised to maintain the highest quality standard.

We use premium materials to ensure our displays last a lifetime.

Highly trained employees and collaboration among departments result in a streamlined process.

All the products are thoroughly inspected using various tests.

Precision Manufacturing Process

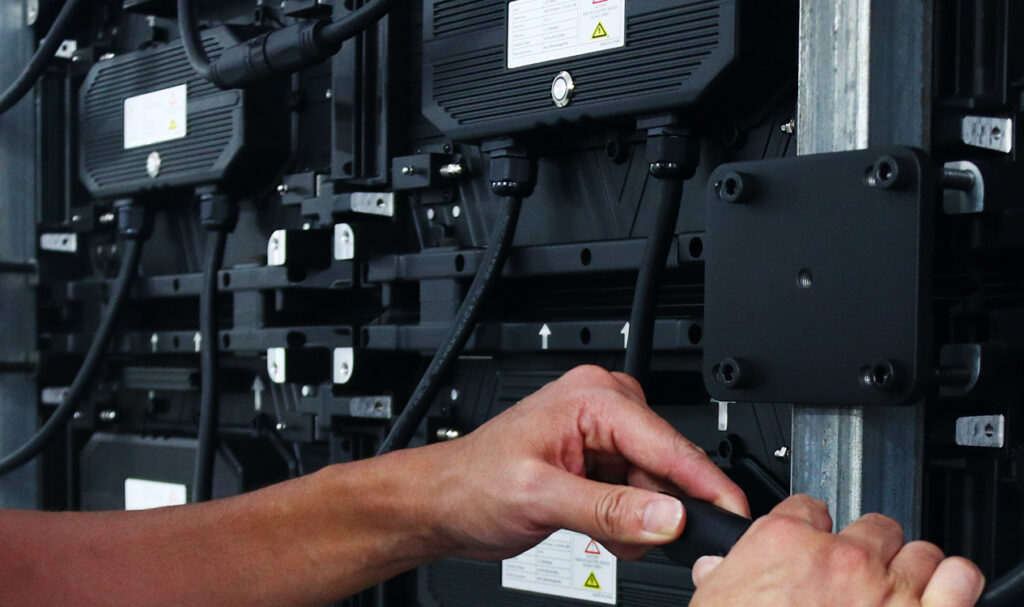

We utilize advanced CNC machines and independently design and manufacture all the necessary components for our products. This ensures precision, quality control, and full customization at every stage of production.

In-house mold development allows us to quickly adapt designs to customer specifications, offering tailored solutions.

CNC machines ensure high-precision production, delivering consistently high-quality LED displays.

Full control over mold design fosters innovation, enabling us to bring new ideas to market more quickly.

Our Trustworthy Raw Material Suppliers

NATIONSTART

The best LED manufacturers

HWA POWER

The outstanding manufacturer of Superior Power Supplies

MOONCELL

The outstanding Control Systems Supplier

Chipone

The leading IC Driver manufacturer

Our Product Testing Protocol

We perform 5 tests to produce our top-quality and reliable LED indoor lighting and outdoor lighting fixtures. Out of these, a few are listed below.

High-Temperature Test

This test involves running the products for 24 hours under 80°C conditions. According to our strict quality protocols, any problematic modules are removed.

Salt Spray Test

Place the module into the machine to simulate coastal environmental conditions, including 70% humidity and a salt concentration of 10 micrograms per cubic meter, and run the test for 24 hours. This test helps evaluate the product’s adaptability under extreme conditions.

Waterproof Test

We simulate rainy conditions and conduct a 12-hour test to check the product’s quality and durability. Our quality control team carefully eliminates any defective parts to ensure optimal waterproof performance.

Freezer Test

Our products are designed to withstand various weather conditions. To test their durability in low temperatures, we place them in a simulated environment of -20°C, run them for 12 hours, and assess their functionality.

Aging Test

After production, all our LED modules undergo a 72-hour aging test to eliminate any burnt or damaged products. Our quality control team rigorously inspects the final product for display color temperature, brightness, and appearance.

Need an Instant Quote For Your Upcoming Projects?

Send us the details and we will get back to you within 24 hours.